Maximizing Performance: The Advantages of YX3 High-Efficiency Motors

Jun 30,2025

Maximizing Performance: The Advantages of YX3 High-Efficiency Motors

Table of Contents

- 1. Introduction to YX3 High-Efficiency Motors

- 2. What are YX3 Motors?

- 3. Key Advantages of YX3 High-Efficiency Motors

- 3.1 Energy Efficiency and Cost Savings

- 3.2 Operational Reliability and Longevity

- 3.3 Environmental Impact and Sustainability

- 4. Applications of YX3 High-Efficiency Motors

- 5. Performance Benchmarks Compared to Traditional Motors

- 6. Maintenance Tips for YX3 Motors

- 7. The Future of Electric Motors and YX3 Innovations

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to YX3 High-Efficiency Motors

In today's fast-evolving industrial landscape, the demand for energy-efficient solutions is at an all-time high. **YX3 high-efficiency motors** are engineered to meet these demands, offering a range of benefits that enhance performance and reduce operational costs. This article delves into the intricacies of YX3 motors, highlighting their features, advantages, applications, and much more.

2. What are YX3 Motors?

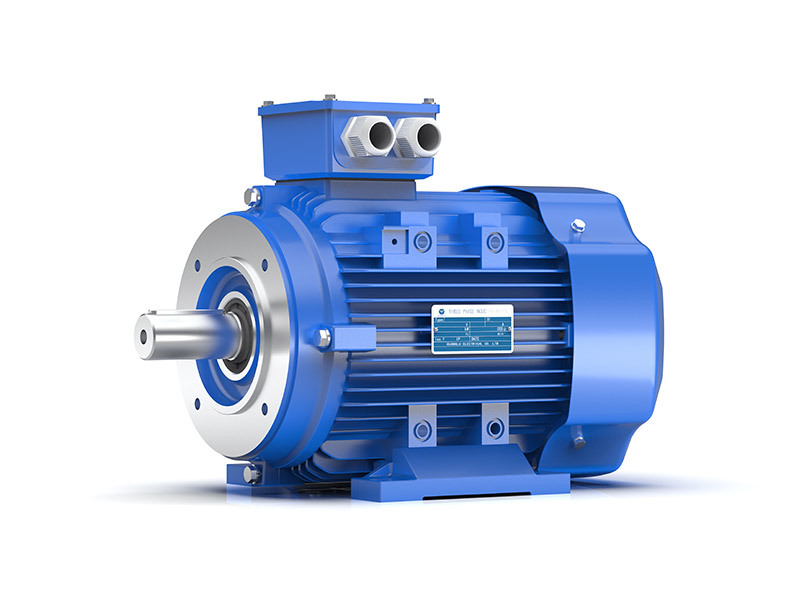

YX3 motors are a series of **high-efficiency electric motors** designed specifically for various industrial applications. They are known for their superior construction, which includes enhanced rotor design, improved winding materials, and advanced cooling techniques. These features contribute to their impressive energy efficiency ratings, making them a preferred choice for manufacturers looking to reduce their energy consumption.

3. Key Advantages of YX3 High-Efficiency Motors

3.1 Energy Efficiency and Cost Savings

One of the most significant advantages of YX3 motors is their exceptional energy efficiency. These motors operate at efficiency levels exceeding 95%, leading to substantial energy savings. Over time, the reduction in energy consumption translates into lower electricity bills, which can significantly offset the initial investment cost of these motors. Businesses can save thousands of dollars annually, making YX3 motors a smart financial decision in the long run.

3.2 Operational Reliability and Longevity

YX3 high-efficiency motors are built with durability in mind. The materials and technologies used in their construction ensure that they can withstand harsh operating conditions. Their robust design minimizes downtime due to failures and maintenance, ensuring continuous operation. With proper maintenance, YX3 motors can last significantly longer than traditional motors, providing added value over time.

3.3 Environmental Impact and Sustainability

In an age where sustainability is paramount, YX3 motors play a crucial role in reducing the carbon footprint of industrial operations. By consuming less energy, these motors contribute to lower greenhouse gas emissions. Furthermore, they align with global initiatives for sustainability, making them an ideal choice for environmentally conscious companies. Investing in YX3 motors not only benefits the bottom line but also supports broader environmental goals.

4. Applications of YX3 High-Efficiency Motors

YX3 high-efficiency motors are versatile and suitable for a wide range of applications. Some key sectors include:

- **Manufacturing**: Used in conveyor systems, pumps, and other machinery requiring reliable motor performance.

- **HVAC Systems**: Essential for fans, compressors, and blowers in heating and cooling systems, enhancing energy efficiency.

- **Water Treatment**: Utilized in pumps and mixers, ensuring efficient operation in water processing facilities.

- **Mining and Quarrying**: Ideal for heavy-duty applications, providing the necessary power and durability in challenging environments.

This adaptability makes YX3 motors a popular choice across various industries.

5. Performance Benchmarks Compared to Traditional Motors

When comparing YX3 high-efficiency motors to traditional electric motors, the differences in performance are stark. Traditional motors typically operate at lower efficiency ratings, often between 85% and 90%. In contrast, YX3 motors can operate at efficiencies of 95% or higher, leading to significant energy savings and reduced operational costs. Additionally, YX3 motors generate less heat during operation, which can help prolong the life of the motor and the equipment it powers.

6. Maintenance Tips for YX3 Motors

To maximize the lifespan and efficiency of YX3 high-efficiency motors, regular maintenance is essential. Here are some practical tips:

- **Routine Inspections**: Regularly check for wear and tear, ensuring that components such as bearings and seals are in good condition.

- **Cleaning**: Keep the motor free from dust and debris, which can impede airflow and cooling.

- **Lubrication**: Ensure all moving parts are adequately lubricated to reduce friction and heat generation.

- **Monitor Temperature**: Keep an eye on the operating temperature of the motor; excessive heat can indicate potential problems.

By following these guidelines, businesses can ensure the longevity and optimal performance of their YX3 motors.

7. The Future of Electric Motors and YX3 Innovations

As technology continues to advance, the future of electric motors, including YX3 models, looks promising. Innovations in materials, control systems, and design are paving the way for even more efficient motors. The integration of smart technology, such as IoT capabilities, allows for real-time monitoring and predictive maintenance, further enhancing the performance and reliability of YX3 motors. Staying ahead of these trends will be vital for businesses seeking to maximize efficiency and minimize costs.

8. Frequently Asked Questions

8.1 What is the efficiency rating of YX3 motors?

YX3 high-efficiency motors typically achieve efficiency ratings of 95% or higher, significantly surpassing traditional motors.

8.2 How do YX3 motors contribute to sustainability?

Through their energy efficiency, YX3 motors reduce electricity consumption and greenhouse gas emissions, supporting environmental sustainability efforts.

8.3 What industries benefit from YX3 motors?

YX3 motors are widely used in manufacturing, HVAC systems, water treatment, mining, and various other industries.

8.4 What maintenance practices are essential for YX3 motors?

Routine inspections, cleaning, lubrication, and temperature monitoring are crucial maintenance practices for YX3 motors.

8.5 How do YX3 motors compare to traditional motors in terms of cost?

While YX3 motors may have a higher upfront cost, their energy savings and longevity lead to lower total operational costs over time.

9. Conclusion

YX3 high-efficiency motors represent a significant advancement in electric motor technology, providing exceptional performance, reliability, and sustainability benefits. By investing in these motors, businesses can enjoy substantial energy savings, reduced operational costs, and contribute positively to environmental goals. As industries continue to evolve, the adoption of YX3 motors will play a pivotal role in driving efficiency and enhancing productivity. Embracing this technology now will ensure a competitive edge in the future.