Exploring the Technical Specifications of IE2 Series Three-Phase Motors: A Comprehensive Guide

Jun 20,2025

Exploring the Technical Specifications of IE2 Series Three-Phase Motors

Table of Contents

- 1. Introduction to IE2 Series Three-Phase Motors

- 2. Understanding IE2 Efficiency Classifications

- 3. Technical Specifications of IE2 Series Motors

- 4. Performance Metrics and Standards

- 5. Applications of IE2 Series Three-Phase Motors

- 6. Benefits of Using IE2 Series Motors

- 7. Installation and Maintenance Tips

- 8. Future Trends in Motor Efficiency Technology

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to IE2 Series Three-Phase Motors

In the realm of electrical engineering, **IE2 Series Three-Phase Motors** stand out due to their high efficiency and reliability. Designed to meet specific performance standards, these motors play a crucial role in various industrial applications. Understanding the technical specifications of IE2 motors can help professionals select the right motor for their needs, effectively enhancing productivity and energy savings.

2. Understanding IE2 Efficiency Classifications

**IE2** is part of the International Electrotechnical Commission (IEC) efficiency classification system for electric motors. This system categorizes motors based on their energy efficiency, with IE2 being the second level of efficiency. The primary goal of the IE2 classification is to reduce electricity consumption and minimize operational costs.

The classification is based on the motor's rated output and efficiency, with IE2 motors demonstrating a minimum efficiency of 85.5% for motors below 7.5 kW and 88.4% for motors between 7.5 kW and 75 kW. The shift towards higher efficiency motors like IE2 not only contributes to global energy conservation efforts but also aligns with increasing regulatory requirements for energy-efficient equipment.

3. Technical Specifications of IE2 Series Motors

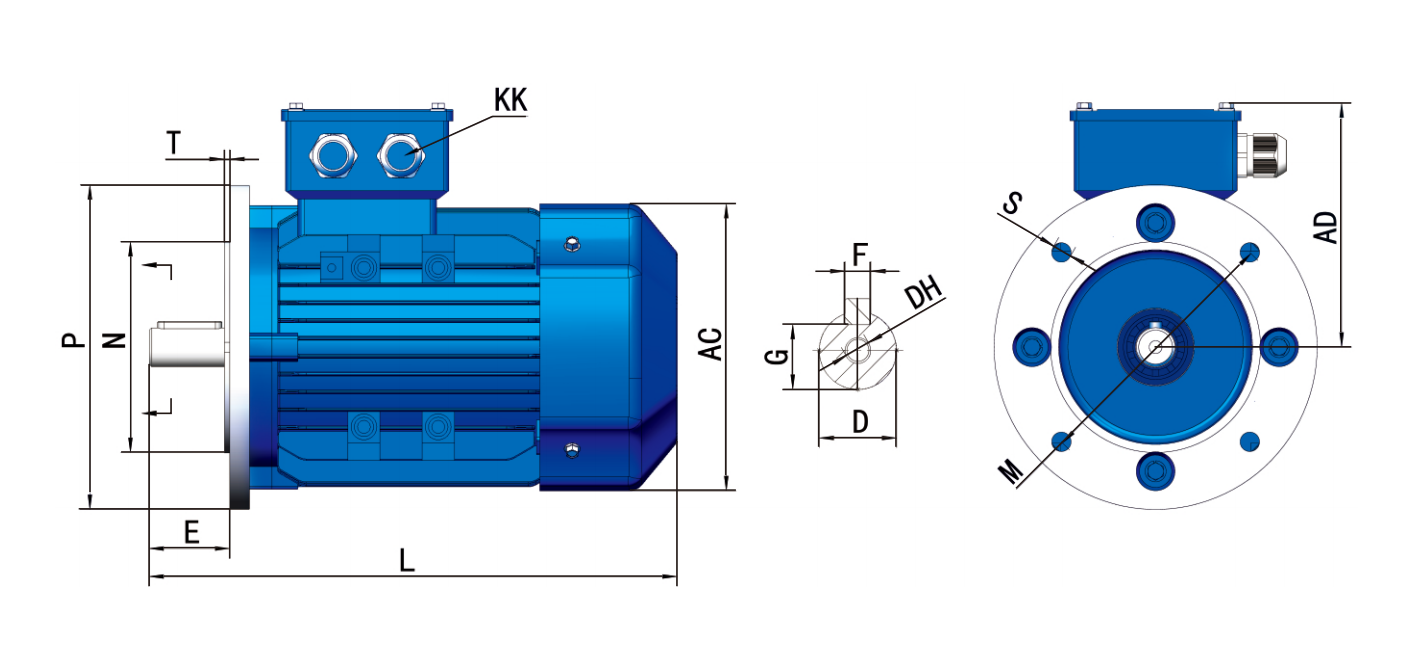

The technical specifications of **IE2 Series Three-Phase Motors** encompass various parameters, including design, dimensions, and electrical characteristics.

3.1 Motor Design and Construction

IE2 motors typically feature robust designs with high-quality materials, ensuring durability and performance. The construction includes:

- **Frame Material**: Usually made of cast iron or aluminum for strength and heat dissipation.

- **Insulation Class**: Generally rated at Class F (155°C) or Class H (180°C), allowing for improved thermal management.

- **Cooling Method**: Often designed with an external fan for better airflow and cooling.

3.2 Electrical Characteristics

Electrical specifications include:

- **Voltage Rating**: Commonly available in 400 V, 230 V, and custom options to accommodate various applications.

- **Frequency**: Standardized at 50 Hz or 60 Hz depending on the region of use.

- **Power Ratings**: Typically range from 0.75 kW to 250 kW, providing flexibility for different operational needs.

3.3 Efficiency Ratings

IE2 motors are engineered for superior performance, achieving higher efficiency ratings compared to older motor classes. The efficiency improvements translate to reduced energy costs, making IE2 motors a cost-effective solution over time.

4. Performance Metrics and Standards

Analyzing the performance of IE2 Series Motors involves various metrics that outline their operational effectiveness.

4.1 Torque and Speed Characteristics

IE2 motors provide consistent torque at various speeds, making them suitable for applications requiring variable speed control. The standard synchronous speed for these motors is typically 1500 RPM or 3000 RPM, depending on the number of poles.

4.2 Vibration and Noise Levels

Designed to minimize operational noise and vibrations, IE2 motors adhere to stringent noise regulations, ensuring a quieter working environment. Vibration levels are maintained within acceptable limits, reducing maintenance needs and prolonging motor life.

4.3 Operational Lifespan

With proper care and maintenance, IE2 motors can operate efficiently over long periods, often exceeding 20,000 hours. Their robust construction and high-grade materials contribute to this extended lifespan, reducing downtime and replacement costs.

5. Applications of IE2 Series Three-Phase Motors

IE2 Series Three-Phase Motors are versatile and used in a wide range of applications, including but not limited to:

5.1 Industrial Machinery

These motors are commonly employed in various industrial machinery such as conveyors, pumps, and compressors, where continuous operation is critical.

5.2 HVAC Systems

In heating, ventilation, and air conditioning systems, IE2 motors provide efficient performance, helping to maintain optimal environmental conditions while reducing energy consumption.

5.3 Agricultural Equipment

Agricultural machinery such as irrigation systems and grain handling equipment also benefit from the high efficiency of IE2 motors, enhancing productivity while minimizing energy costs.

6. Benefits of Using IE2 Series Motors

The use of **IE2 Series Three-Phase Motors** brings numerous benefits to industries and applications:

6.1 Energy Efficiency

One of the most significant advantages of IE2 motors is their energy efficiency. By consuming less electricity compared to lower-efficiency motors, these motors help businesses reduce their operational expenses and carbon footprint.

6.2 Cost Savings

The initial investment in IE2 motors may be higher, but the long-term savings on energy costs make them a financially sound choice. Lower maintenance requirements also contribute to overall cost efficiency.

6.3 Regulatory Compliance

As governments worldwide tighten regulations around energy consumption, IE2 motors help businesses stay compliant with energy efficiency mandates, avoiding potential fines and enhancing their corporate social responsibility profile.

7. Installation and Maintenance Tips

To maximize the performance and lifespan of IE2 motors, proper installation and maintenance practices are crucial.

7.1 Installation Guidelines

- Ensure the motor is mounted on a sturdy base to minimize vibrations.

- Align the motor with the driven equipment to prevent unnecessary stress on bearings.

- Verify that the electrical connections are secure and adhere to local electrical codes.

7.2 Maintenance Practices

- Regularly inspect the motor for signs of wear or damage.

- Maintain clean ventilation paths to ensure effective cooling.

- Schedule routine checks on electrical connections and lubricant levels.

8. Future Trends in Motor Efficiency Technology

The landscape of motor technology is evolving rapidly, driven by the need for higher efficiency and sustainability.

8.1 Advancements in Materials

New materials, such as superconductors and high-performance magnets, are being explored to enhance motor efficiency and reduce energy losses further.

8.2 Smart Motor Technologies

The integration of IoT (Internet of Things) technologies will enable real-time monitoring and predictive maintenance, helping businesses optimize motor performance and reduce downtime.

9. Frequently Asked Questions

9.1 What distinguishes IE2 motors from other efficiency classes?

IE2 motors are designed to achieve higher efficiency levels than lower classes, focusing on significant energy savings and reduced operational costs.

9.2 Can IE2 motors replace older motor types?

Yes, IE2 motors can replace older, less efficient motor types, leading to improved energy efficiency and compliance with modern energy regulations.

9.3 What is the average lifespan of an IE2 motor?

With proper maintenance, IE2 motors can last over 20,000 hours, making them a durable option for industrial applications.

9.4 Are IE2 motors suitable for variable speed applications?

Yes, IE2 motors are well-suited for variable speed applications, providing consistent performance across different operating conditions.

9.5 How do I choose the right IE2 motor for my application?

Consider factors such as power requirements, operating environment, and specific application needs when selecting an IE2 motor.

10. Conclusion

In conclusion, **IE2 Series Three-Phase Motors** represent a significant advancement in motor efficiency technology. By understanding their technical specifications, performance metrics, and applications, industry professionals can make informed decisions that lead to enhanced productivity and cost savings. The transition to IE2 motors not only supports energy conservation efforts but also positions businesses favorably in an increasingly competitive market. Embracing these advanced motors ensures compliance with regulatory standards while contributing to a sustainable future.