How IE2 Three-Phase Motors are Revolutionizing Manufacturing

Apr 21,2025

How IE2 Three-Phase Motors are Revolutionizing Manufacturing

Table of Contents

- Introduction to IE2 Three-Phase Motors

- Understanding IE2 Motors: A Technical Overview

- Energy Efficiency and Sustainability in Manufacturing

- Advantages of IE2 Three-Phase Motors

- Applications of IE2 Three-Phase Motors in Various Industries

- Cost Savings and Return on Investment from IE2 Motors

- The Future of IE2 Motors in the Manufacturing Sector

- Frequently Asked Questions

- Conclusion

Introduction to IE2 Three-Phase Motors

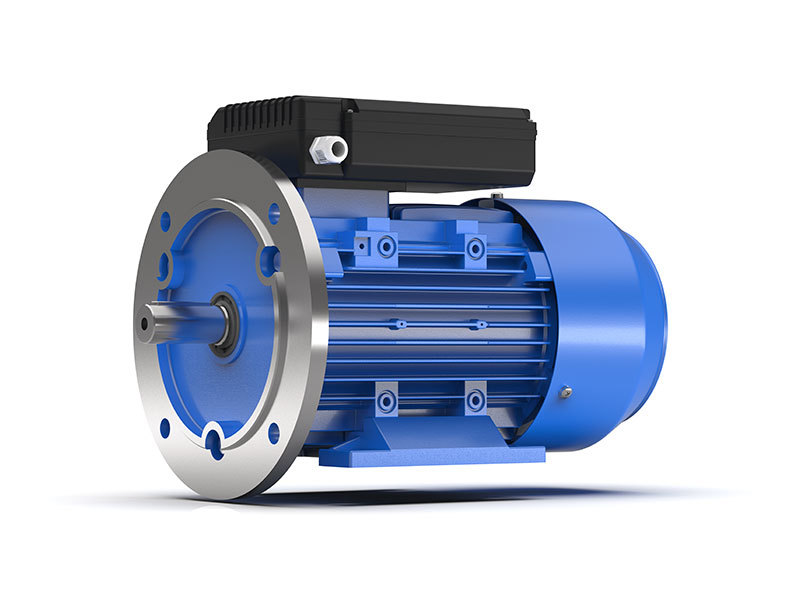

The manufacturing sector is undergoing a significant transformation, driven by advancements in technology and the demand for greater energy efficiency. One of the key players in this evolution is the **IE2 three-phase motor**, which has become a vital component in various applications. These motors stand out not only for their performance but also for their ability to significantly reduce energy consumption and operational costs. In this article, we will delve into the characteristics, benefits, and applications of IE2 three-phase motors, illustrating how they are revolutionizing the manufacturing landscape.

Understanding IE2 Motors: A Technical Overview

The IE2 classification refers to energy efficiency standards defined by the International Electrotechnical Commission (IEC). Three-phase motors are widely utilized in industrial settings due to their robustness and efficiency. Here are some crucial technical aspects to consider:

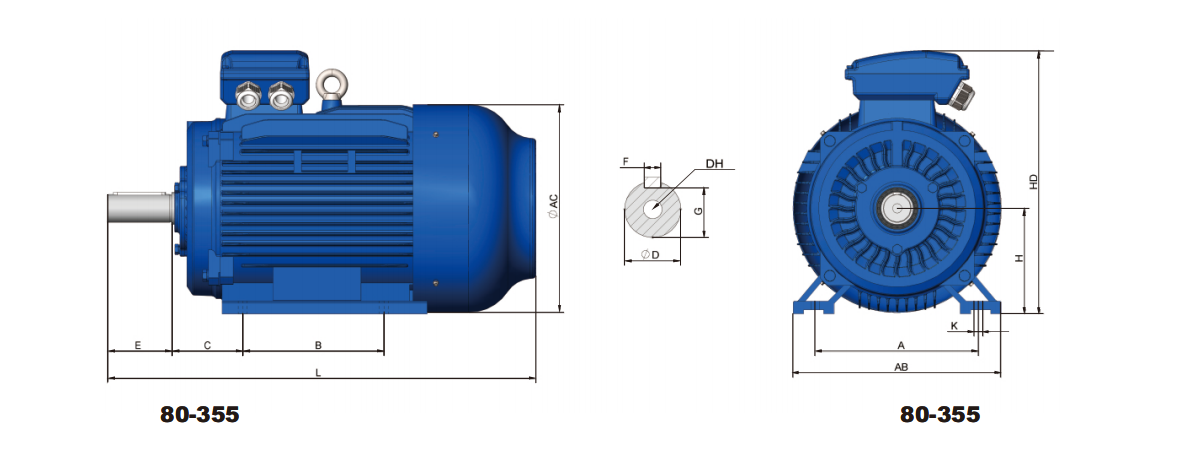

The Construction of IE2 Three-Phase Motors

IE2 three-phase motors typically feature a squirrel cage rotor design, which enhances durability and minimizes maintenance requirements. The **high-quality materials** used in their construction contribute to improved thermal performance and energy efficiency.

Efficiency Ratings Explained

IE2 motors must meet specific efficiency criteria, making them up to 10% more efficient than traditional IE1 motors. This efficiency translates into lower energy costs, which is a critical consideration for manufacturers aiming to optimize their operations.

Energy Efficiency and Sustainability in Manufacturing

Energy efficiency is not merely a buzzword; it has become a cornerstone of modern manufacturing practices. The pursuit of sustainability has led many companies to adopt technologies that minimize energy consumption. IE2 three-phase motors are at the forefront of this movement.

Reducing Carbon Footprint

By utilizing IE2 motors, manufacturers can make significant strides in reducing their carbon footprint. These motors consume less electricity compared to traditional counterparts, leading to lower greenhouse gas emissions. This aspect resonates with environmentally conscious consumers and regulators alike.

Compliance with Energy Efficiency Regulations

Governments worldwide are implementing stricter energy efficiency regulations. Transitioning to IE2 three-phase motors allows manufacturers to comply with these regulations, avoiding potential fines and enhancing their brand reputation.

Advantages of IE2 Three-Phase Motors

The adoption of IE2 three-phase motors offers several advantages that contribute to their growing popularity in the manufacturing sector.

High Performance and Reliability

IE2 motors are designed for high performance, offering superior torque and speed characteristics. Their reliability ensures consistent operation, which is essential for continuous manufacturing processes.

Lower Operational Costs

One of the most compelling reasons to switch to IE2 motors is the potential for cost savings. These motors consume less electricity, translating to lower utility bills. Additionally, their durability means less frequent replacements and lower maintenance costs.

Versatility in Applications

IE2 three-phase motors are versatile and can be used across various applications in different manufacturing sectors. From conveyor systems to pumps and compressors, their adaptability makes them a preferred choice among industrial operators.

Applications of IE2 Three-Phase Motors in Various Industries

The versatility of IE2 three-phase motors allows them to thrive in diverse industrial applications. Here are some notable examples:

Manufacturing and Assembly Lines

In manufacturing environments, IE2 motors power assembly lines and robotic systems, aiding in the efficient production of goods. Their energy efficiency directly contributes to more cost-effective operations.

Food and Beverage Industry

In the food and beverage industry, hygiene and reliability are paramount. IE2 motors are used in mixing, pumping, and packaging applications, providing the efficiency needed to meet production demands while adhering to strict regulatory standards.

Water and Wastewater Treatment

Water treatment facilities utilize IE2 three-phase motors for pumps and blowers, optimizing energy consumption while ensuring the effective treatment of water. The reliability of these motors is crucial in maintaining operation without interruptions.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems often employ IE2 motors to enhance energy efficiency. By reducing energy consumption, these motors contribute to lower operational costs for commercial buildings and factories.

Cost Savings and Return on Investment from IE2 Motors

Investing in IE2 three-phase motors can yield significant financial benefits for manufacturers.

Long-Term Savings

While the initial investment in IE2 motors might be higher than traditional motors, the long-term savings on energy bills often outweigh the upfront costs. Manufacturers can expect to recover their investment quickly through reduced energy expenses.

Increased Productivity and Efficiency

The operational efficiency provided by IE2 motors translates into increased productivity. With these motors, machines can operate at higher capacities with fewer interruptions, leading to a more streamlined manufacturing process.

Enhanced Competitive Advantage

Manufacturers that adopt energy-efficient practices can market themselves as environmentally friendly, attracting customers who prioritize sustainability. This competitive advantage can lead to increased market share and profitability.

The Future of IE2 Motors in the Manufacturing Sector

As technology continues to advance, the role of IE2 three-phase motors in manufacturing is expected to grow. Innovations in motor design, materials, and control systems will enhance their efficiency and performance even further.

Integration with Smart Manufacturing Systems

The rise of Industry 4.0 and smart manufacturing systems presents new opportunities for IE2 motors. Integrated with IoT technologies, these motors can provide real-time data analytics, further optimizing energy consumption and operational efficiency.

Continued Regulatory Support

With ongoing global initiatives aimed at reducing energy consumption and promoting sustainability, IE2 motors are likely to remain a vital part of manufacturing. As regulations become more stringent, the adoption of energy-efficient technologies will only increase.

Frequently Asked Questions

What are IE2 three-phase motors?

IE2 three-phase motors are energy-efficient electric motors that meet specific efficiency standards set by the International Electrotechnical Commission. They are commonly used in industrial applications due to their high performance and reliability.

How do IE2 motors improve energy efficiency?

IE2 motors consume less electricity compared to traditional motors, which reduces overall energy costs and helps manufacturers achieve sustainability goals.

What industries benefit the most from IE2 three-phase motors?

IE2 motors are employed across various industries, including manufacturing, food and beverage, water treatment, and HVAC systems, showcasing their versatility.

Are IE2 motors more expensive than traditional motors?

While IE2 motors may have a higher initial cost, the long-term savings on energy expenses and reduced maintenance costs often make them a more cost-effective option.

What is the expected lifespan of IE2 three-phase motors?

IE2 motors are designed for durability and can last many years with proper maintenance, often outlasting traditional motors.

Conclusion

The integration of **IE2 three-phase motors** in manufacturing is not just a trend; it represents a fundamental shift towards energy efficiency and sustainability. These motors offer significant advantages, including reduced operational costs, enhanced productivity, and compliance with environmental regulations. As industries continue to evolve, the role of IE2 motors will only expand, driving manufacturers toward a more sustainable and efficient future. Embracing this technology is not merely beneficial; it is essential for businesses aiming to thrive in the competitive manufacturing landscape.