Why TMYC Motors Are Essential for Sustainable Manufacturing

Apr 16,2025

Why TMYC Motors Are Essential for Sustainable Manufacturing

Table of Contents

1. Introduction to TMYC Motors

2. The Importance of Sustainability in Manufacturing

3. Key Features of TMYC Motors

3.1 Energy Efficiency

3.2 Durability and Reliability

3.3 Smart Technology Integration

4. Applications of TMYC Motors in Various Industries

4.1 Automation and Robotics

4.2 Renewable Energy Systems

4.3 HVAC Systems

5. How TMYC Motors Contribute to Sustainable Practices

5.1 Reduced Energy Consumption

5.2 Lower Carbon Footprint

5.3 Waste Reduction

6. Case Studies: Successful Implementation of TMYC Motors

7. Future Trends in Motor Technology

8. Conclusion

9. FAQs

1. Introduction to TMYC Motors

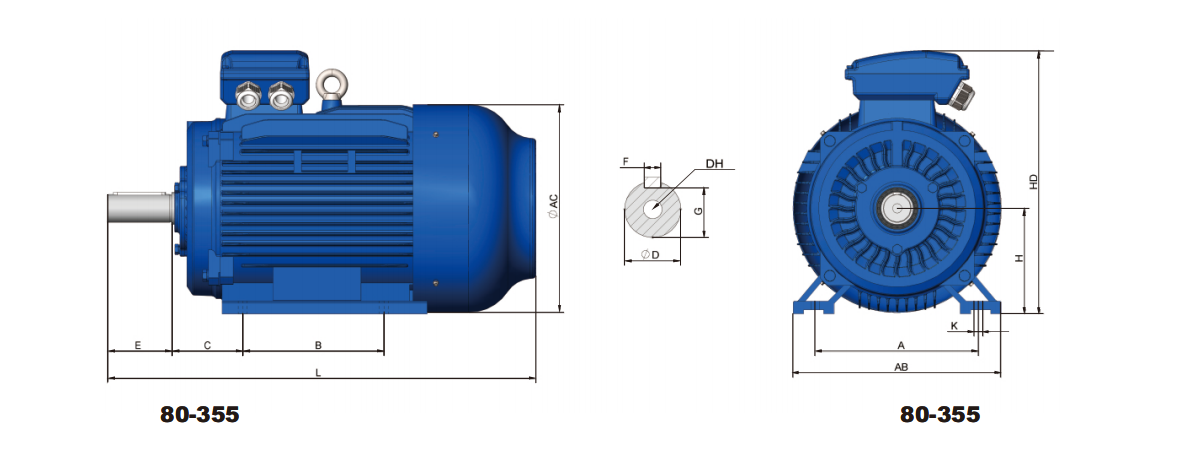

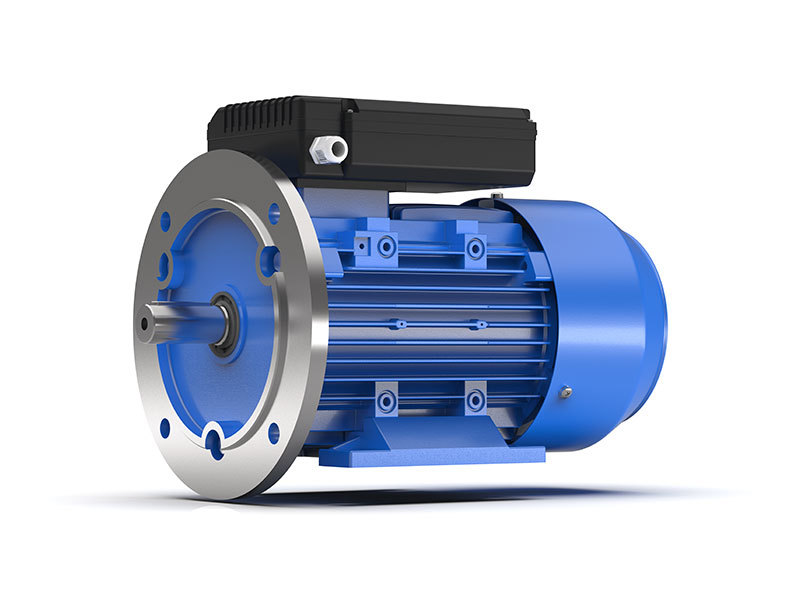

TMYC motors have emerged as a revolutionary force in the realm of sustainable manufacturing. These high-performance electric motors are designed to meet the increasing demands for energy efficiency and environmental responsibility in various industrial applications. With advancements in technology, TMYC motors not only deliver superior performance but also align with the global shift toward more sustainable manufacturing practices.

2. The Importance of Sustainability in Manufacturing

Sustainability in manufacturing is no longer just a trend; it has become a necessity. As industries face increasing scrutiny over their environmental impact, the focus has shifted toward practices that promote sustainability. This includes reducing energy consumption, minimizing waste, and lowering carbon emissions. Companies are adopting innovative technologies to enhance their sustainability efforts, and TMYC motors are at the forefront of this movement.

3. Key Features of TMYC Motors

TMYC motors are distinguished by their unparalleled features that contribute to their essential role in sustainable manufacturing.

3.1 Energy Efficiency

One of the standout features of TMYC motors is their **energy efficiency**. These motors are designed to operate with minimal energy consumption while maximizing output. By utilizing advanced materials and designs, TMYC motors reduce energy usage, which subsequently lowers operational costs for manufacturers.

3.2 Durability and Reliability

Manufacturers require motors that can withstand demanding conditions while delivering consistent performance. TMYC motors are built with **durability** in mind, ensuring they can handle various environmental factors without compromising functionality. This reliability translates to fewer replacements and repairs, contributing to sustainable practices by reducing resource consumption over time.

3.3 Smart Technology Integration

In today’s digital age, integration with smart technology is crucial. TMYC motors incorporate **smart technology** that allows for real-time monitoring and control. This capability enables manufacturers to optimize their operations, predict maintenance needs, and streamline processes, further enhancing sustainability efforts.

4. Applications of TMYC Motors in Various Industries

TMYC motors find applications across a multitude of industries, showcasing their versatility and effectiveness in promoting sustainable manufacturing.

4.1 Automation and Robotics

In the realm of automation, TMYC motors are pivotal in driving robotic systems that enhance production efficiency. By automating repetitive tasks, these motors not only speed up production but also minimize energy use, making manufacturing processes more sustainable.

4.2 Renewable Energy Systems

The shift toward renewable energy is critical in combating climate change. TMYC motors play a vital role in renewable energy systems, such as wind turbines and solar panels. Their efficiency and reliability help maximize energy output, promoting a cleaner energy future.

4.3 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems contribute significantly to energy use in buildings. TMYC motors are used in these systems to improve energy efficiency, which leads to reduced energy consumption and lower greenhouse gas emissions.

5. How TMYC Motors Contribute to Sustainable Practices

TMYC motors not only enhance operational efficiency but are also instrumental in implementing sustainable practices across various sectors.

5.1 Reduced Energy Consumption

By utilizing **high-efficiency designs**, TMYC motors consume significantly less energy compared to traditional motors. This reduction is crucial for manufacturers aiming to lower their energy bills and carbon footprint.

5.2 Lower Carbon Footprint

The application of TMYC motors contributes to a **lower carbon footprint**. Through efficient operation and reduced energy consumption, companies can significantly decrease their greenhouse gas emissions, making them more environmentally friendly.

5.3 Waste Reduction

TMYC motors also aid in **waste reduction**. Their durability means fewer replacements are needed over time, resulting in less waste generated from discarded motors. Furthermore, the energy efficiency of these motors reduces the overall demand for energy, which in turn minimizes the waste associated with energy production.

6. Case Studies: Successful Implementation of TMYC Motors

Numerous companies have successfully integrated TMYC motors into their operations, showcasing the benefits of these advanced motors. For instance, a leading automotive manufacturer implemented TMYC motors in their assembly line, resulting in a 20% reduction in energy consumption. This not only improved their bottom line but also enhanced their reputation as a sustainable manufacturer.

Another case involves a renewable energy company that adopted TMYC motors in their wind turbine systems. The integration led to a 15% increase in energy output, demonstrating the motors' effectiveness in enhancing renewable energy production.

7. Future Trends in Motor Technology

As technology continues to evolve, so too will the capabilities of motors like those produced by TMYC. Future trends indicate a growing focus on smart technologies, with an emphasis on IoT integration, further enhancing operational efficiency and sustainability. Additionally, advancements in materials science will likely lead to even more efficient and durable motor designs, pushing the boundaries of what is currently possible.

8. Conclusion

TMYC motors are essential for sustainable manufacturing, offering a range of features that enhance energy efficiency, reliability, and performance. Their applications across various industries not only contribute to reduced energy consumption and waste but also play a vital role in the global shift towards sustainable practices. As we advance into a future focused on sustainability, TMYC motors will undoubtedly remain at the forefront, driving innovation and change in the manufacturing landscape.

9. FAQs

1. What are TMYC motors?

TMYC motors are high-performance electric motors designed for efficiency and reliability, playing a crucial role in sustainable manufacturing practices.

2. How do TMYC motors improve energy efficiency?

TMYC motors utilize advanced materials and designs that minimize energy consumption while maximizing output, leading to significantly reduced energy usage.

3. In which industries are TMYC motors commonly used?

TMYC motors are used in various industries, including automation, renewable energy systems, and HVAC applications.

4. What are the environmental benefits of using TMYC motors?

The use of TMYC motors contributes to a lower carbon footprint, reduced energy consumption, and waste reduction, promoting more sustainable practices.

5. Are TMYC motors compatible with smart technology?

Yes, TMYC motors are designed for integration with smart technology, enabling real-time monitoring and control to optimize manufacturing processes.